High end equipment for high precision and accuracy of output

JS Autocast incorporates bench-marked testing facilities to ensure the highest possible standards for each of its finished products. We are one of the few foundries in India with extensive in-house testing capabilities.

Our testing capabilities are complemented by the extensive research facilities at KCTI, Pune.

Some of the testing equipment comprise of:

- Chemical testing – 2 X 31-element spectrometers

- Mechanical testing - Universal Testing Machine (UTM), Impact analyzer with subzero bath, Fatigue and fracture testing

- Optical testing – Carl Zeiss Metallurgical microscope with image analyzer.

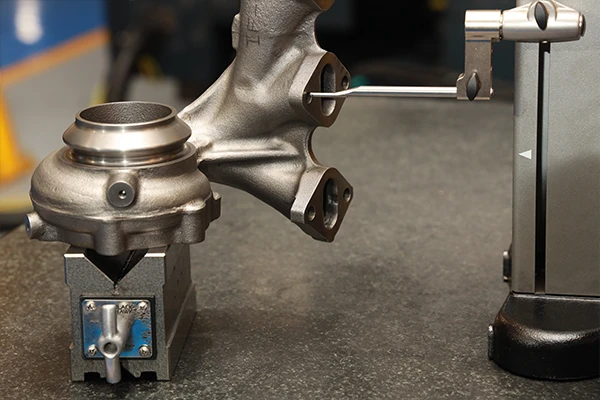

- Dimensional testing - CMM with scanning probe, Contour profile tracer and Height gauges.

- NDT Testing - (UT & MPI)—Level II, Rad check meter, 3D Scanning, Endoscopy, videoscopy.

Design Engineering and Product Development

JS Autocast has an in-house team of professionals for casting design & simulation.

View More

Melting & Pouring

We at JS Autocast are committed to adhere with the industry's best Metal Melting practices.

View More

Post Production Process

The quality of the castings manufactured depends on the moulds' precision.

View More

Machine Shop

The In-house machining capabilities gives us an unrivaled command over the quality of the manufactured castings.

View More

Packaging

JS Autocast uses Benchmarked standards for packaging to ensure safety and hygiene of the casting while shipment.

View More