In-house team of professionals for design & Simulation

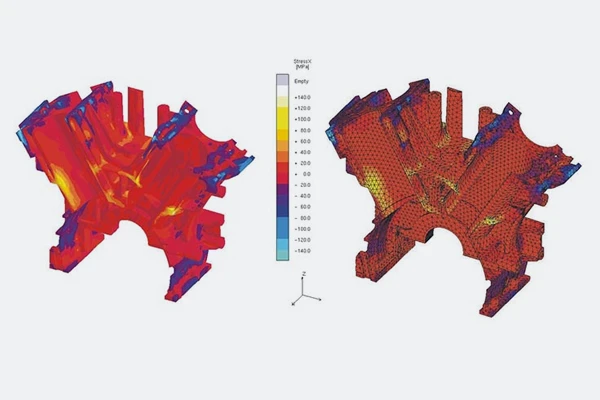

The use of Magma Iron software ensures defect-free casting models that meet the customer requirements in every aspect. JSA gives extra care to the casting patterns with predetermined design measurements.

Technical reviews are conducted with the customer during the design phase itself to ensure agile and efficient development of the casting. A dedicated and strong product development team has enabled us to produce over 160 new products in FY23. Some of our design capabilities include:

Our design team follows the following procedures

- Conversion of 2D drawings into 3D design models - solid works

- Magma Iron Software for defect-free simulation

- Pre-design casting & machining tools - to shorten the product development lead times

Melting & Pouring

We at JS Autocast are committed to adhere with the industry's best Metal Melting practices.

View More

Post Production Process

The quality of the castings manufactured depends on the moulds' precision.

View More

Machine Shop

The In-house machining capabilities gives us an unrivaled command over the quality of the manufactured castings.

View More

Testing and Quality Analysis

The precision and accuracy of the testing equipment is key to delivery of quality castings.

View More

Packaging

JS Autocast uses Benchmarked standards for packaging to ensure safety and hygiene of the casting while shipment.

View More