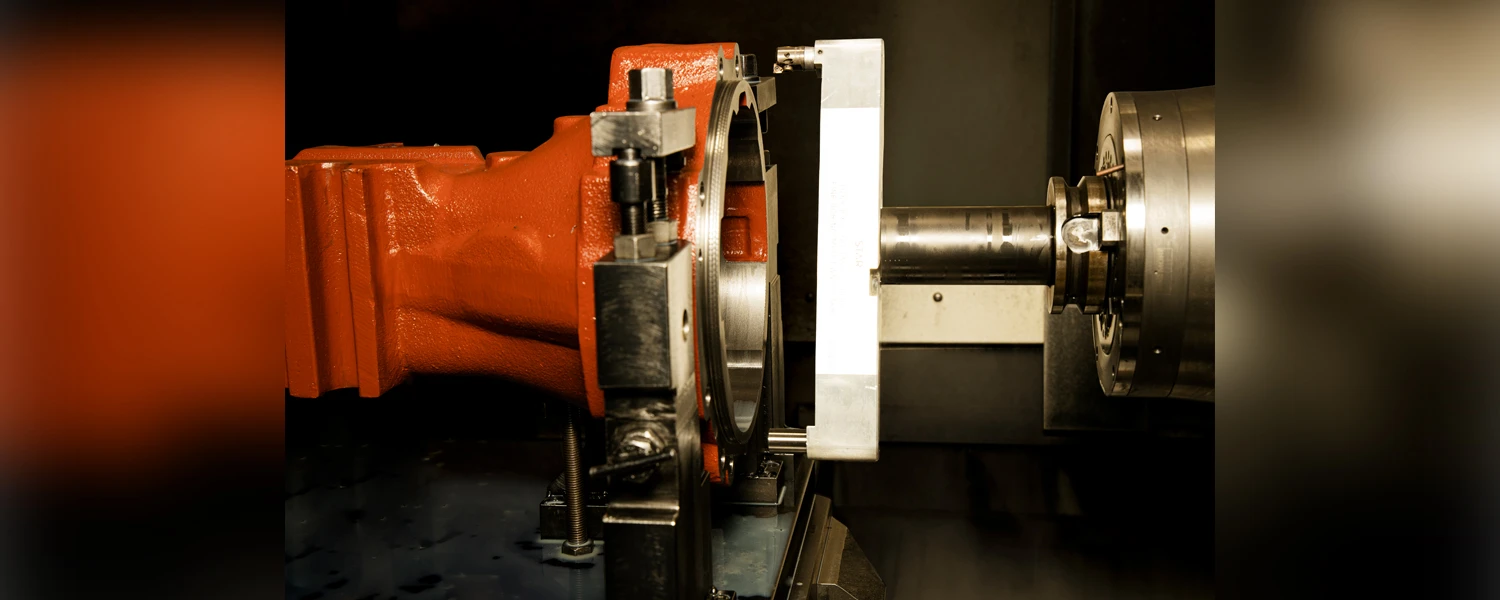

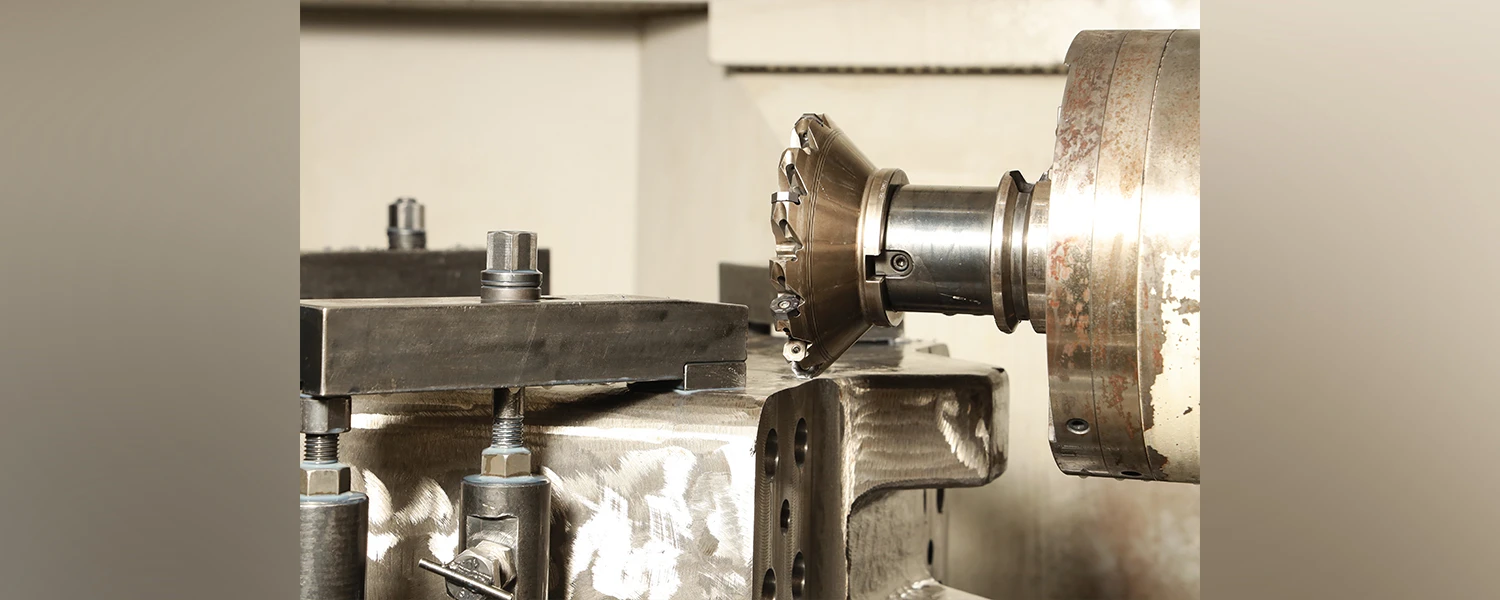

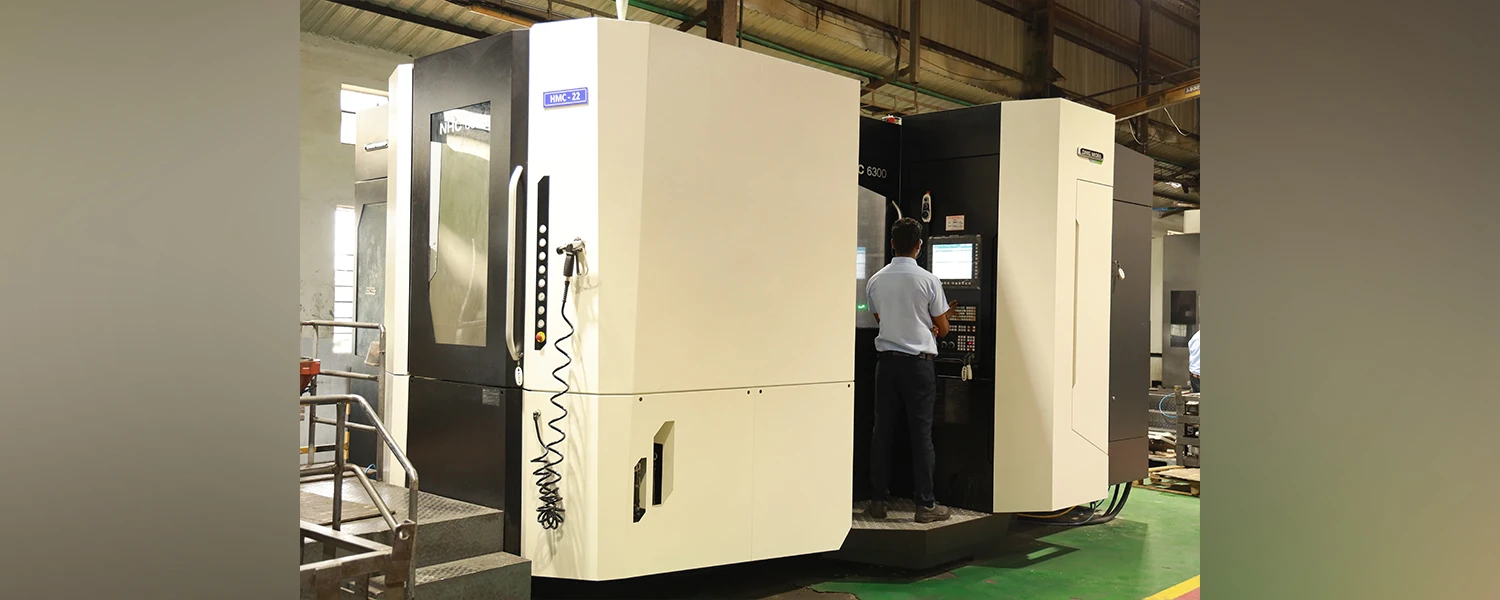

Integrated machining facility for better quality control

Our machining infrastructure is equipped to complement our foundry capabilities. JSA uses state-of-the-art machinery (Mazak, DMG and others) to produce machined castings to suit the requirements of end customers.

Nearly 90% of the castings shipped from our facility are fully machined. Today we have >120 CNC machines installed across two facilities in coimbatore capable of machining >20,000 tons per annum. In addition, we have over the years developed reliable out-sourcing options.

We have a dedicated NPD cell with exclusive machines and a team for new product development.

Design Engineering and Product Development

JS Autocast has an in-house team of professionals for casting design & simulation.

View More

Melting & Pouring

We at JS Autocast are committed to adhere with the industry's best Metal Melting practices.

View More

Post Production Process

The quality of the castings manufactured depends on the moulds' precision.

View More

Testing and Quality Analysis

The precision and accuracy of the testing equipment is key to delivery of quality castings.

View More

Packaging

JS Autocast uses Benchmarked standards for packaging to ensure safety and hygiene of the casting while shipment.

View More